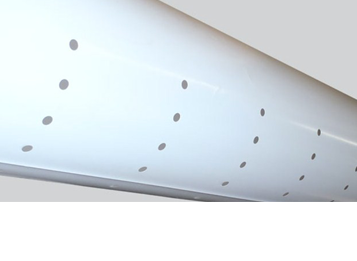

Air distribution hoses

Developments at (OCR) never stop and that’s why we have now introduced new air distribution hoses.

Why another new air distribution hose? There are already so many around. That’s true, but our air distribution hoses work differently from regular air socks. Regular air socks are made of fabric, giving them little pores through which the air is blown in a 360˚ range, i.e. all around, exposing it to a lot of counter pressures. This makes it almost impossible to feel that air is coming out at all. The air descends so slowly that what should have been cool air has warmed up again before reaching the crop. Regular air socks clog up within a matter of weeks, reducing their capacity, possibly even to the extent that no air can get in at all. And the low air speed requires the use of fans to circulate the surplus stagnant air.

What is different about our air distribution hoses?

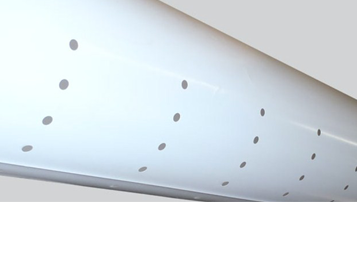

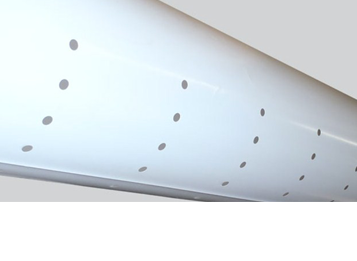

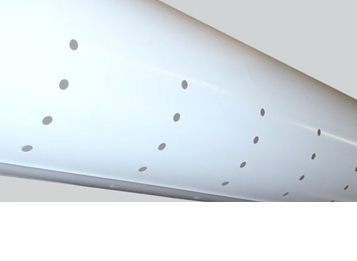

Our air distribution hoses are made of high-quality, antistatic, transparent LPDE foil with little round holes punched into it along a 120˚ area, i.e. 1/3 of a circle. The air can therefore be aimed more precisely and blown out at a higher speed. This is based on calculations, so that you can make sure your air distribution hose complies with the right specifications to provide you with the capacity you need.

Your benefits:

1. Targeted air distribution.

2. The transparent foil lets light through.

3. Cannot clog up.

4. Higher air speed: no fans needed.

5. Always the right capacity thanks to proper calculations.